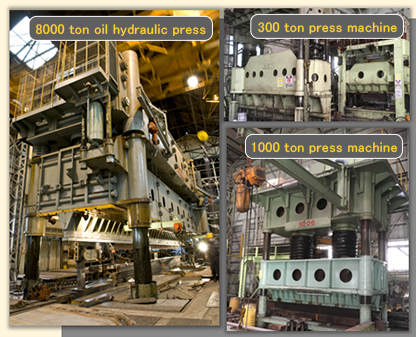

Manufacture of products by press working, cutting, plate working and machining mainly with Japan's largest 8000-t continuous press.

Since the establishment in 1946, we have extended our business mainly in the large-scale press working field and been engaged in cutting plates, large-scale press working and plate working in various industries, including shipbuilding, sluice gates, bridges and construction machinery, starting from columns and centers of trains. At present, we are involved in more extended business and are making every effort at production and improvement in the environment-related plant and mine development machinery fields utilizing our accumulated technologies.

- [Outline of Plant]

- *Site area: 14,500m²

*Building area: 9,300m²

- [Major equipment of Senshu Koki]

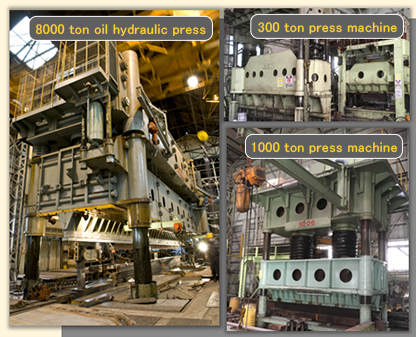

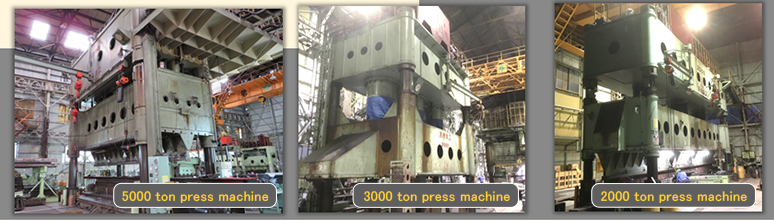

- 1. Press machine: 7 units, made by Kawasaki Hydromechanics Corporation

- *8,000t (Max. output: 8,000ton・f, Max. stroke: 1,500mm, Bed size: 18,500×3,500mm)

*5,000t (Max. output: 5,000ton・f, Max. stroke: 1,600mm, Bed size: 3,000×6,000mm)

*3000t ・ 2000t ・ 1000t ・ 300tx2

- 2.Laser cutting machine : 1 unit, made by Nissan Tanaka Corporation

- *Carbon dioxide laser oscillator: out put 6kw

*Effective cutting width 2,600mm

*Effective cutting length 25,300mm

- 3. Welding robot : 2units

- *Arm welding robot (Stroke 1,800mm , 1,400mm each one), made by Panasonic

- 4. Radial drilling machine : 1 unit, made by Osumi Iron Works Corporation

- 5. Overhead crane

- *20t: 16.9m, 17.7m×each one *15t: 16.8m×1 unit *10t: 18.1m×1 unit

*7.5t: 13.9m, 16.4m×each one *5t×2 units *2.8t×2 units

Our bending work is one of the best on quality, for instance 5000-t continuous press can bend metal plates 100 or more mm tick, and 8000-t continuous press can bend a 20m length of metal plate. We have other machines such as 300-t, 1000-t and 2000-t, which make it possible to process according to various purposes such as special bending and straightening.

- We have a compact, high-performance carbon dioxide gas laser oscillator (6kw), which improves efficiency by making, the most of a wide range of cutting surface plate. (Effective cutting wides : 2,600mm, effective cutting length : 25,300mm ) Our factory uses an integrated manufacturing system standardized from parts on through to finished product, which further improves efficiency.

- On a regular basis, several kinds of lectures are held in order to improve operator’s assembly technique and welding technique, and we positively support acquisition of a qualification of our employees.